Continuing on our last post with space being a profit driver, we continue with talking about efficiency and productivity being a profit driver. Considering that our core business is about creating space, maximizing efficiency, and increasing profitability – we know that taking care of the first two items help make possible the third.

Continuing on our last post with space being a profit driver, we continue with talking about efficiency and productivity being a profit driver. Considering that our core business is about creating space, maximizing efficiency, and increasing profitability – we know that taking care of the first two items help make possible the third.

Efficiency is more obvious as a profit driver than space, yet we find many businesses still struggle to find the right solutions to create the most productive workflow. We work with many auto dealerships throughout the Northeast so consider this for a minute – every wasted minute of your technician’s time waiting for parts costs you $1.50. If you have 10 technicians each waiting 5 minutes a day, it can cost you over $15,000 in lost billable hours!

The same holds true for warehouse employees or anyone involved in distribution. Understanding the cost of inefficiency can help you improve your systems, get the right equipment in place, and in turn increase your profitability.

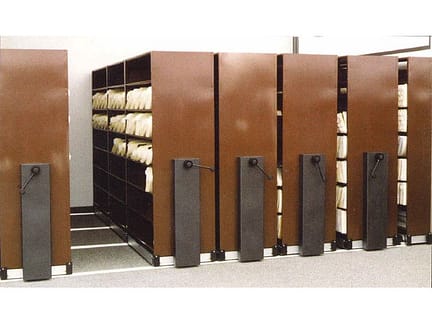

Some of the ways we help improve your employee productivity is by re-arranging inventory to be most cost effective. Understanding what inventory you use most and designing the right system to put the top 20% most active items closest to those who need it, helps improve productivity and ultimately your bottom line. Creating the right warehouse systems with the right racking and correct layout also helps maximize the efficiency of your workflow.

We have helped several companies improve their bottom line by helping improve efficiency. We offer our proven Operational Efficiency Analysis [link this to that page] and Materials Handling System Design [link to that page] to help your business run smoother. To see how we can help improve your workflow and improve efficiency, call us today at (973) 227-0018 or fill out the More Information form to the left.